HOW OUR COFFEE IS PROCESSED

Each farmer will begin by selectively handpicking only the ripest red cherries from their plantations which is labour intensive work and requires multiple harvests throughout the season to allow those cherries that need it, a little more time to mature.

Once harvested, each farmer will then hand sort and sieve their cherries to remove any defects or overly small cherries. The cherries are then floated in a tank to further remove any defects with low density beans floating to the surface and removed due to either being underripe or insect damaged. From here, they are then pulped (by a traditional hand pulping machine at individual households) to remove the skin of the cherry and the flesh of the fruit, leaving the coffee seed covered in mucilage which is again floated for a second time to remove any ‘bad’ beans that will float to the surface.

The mucilage covered seeds are now ready for fermentation and a ‘baldi’ is used (essentially a large bucket with a lid) to ferment the coffee. It is incredibly important that clean and fresh water is used in this process and this usually comes directly from nearby mountain sources which are plentiful in Letefoho. 20 kilos of coffee is fermented at a time, with the coffee left completely immersed in water (anaerobic fermentation) for between 40 – 44 hours whilst the natural sugars in the mucilage are broken down which contributes to the unique flavour development of our coffees.

Traditionally farmers will know that the fermentation process is complete when the coffee feels scratchy, similar to when pebbles are rubbed together. In addition to traditional methods, we also use Ph meters to confirm when fermentation is complete and the sweet spot for our coffee is between Ph 4.0 – 4.2. However, we have learnt over the years that a farmers’ intuition and experience is as good a tool, if not better, than a Ph meter. Once fermentation is complete, the coffee is then washed. This is an intense process which can require up to 8-10 washes in order to ensure that the parchment is ‘fully-washed’ and is crucial in order to achieve the clean cup profile expected and associated with our coffees.

(Some people may not be aware that the waste water produced from this process is highly acidic and can cause great damage to localised flora and fauna if not managed appropriately. With this in mind, the resulting waste water is collected in small channels filled with rocks that filter the water safely back into the ground.)

Joaquim from the Cristo Liurai group pulping his coffee cherries with a manual pulping machine.

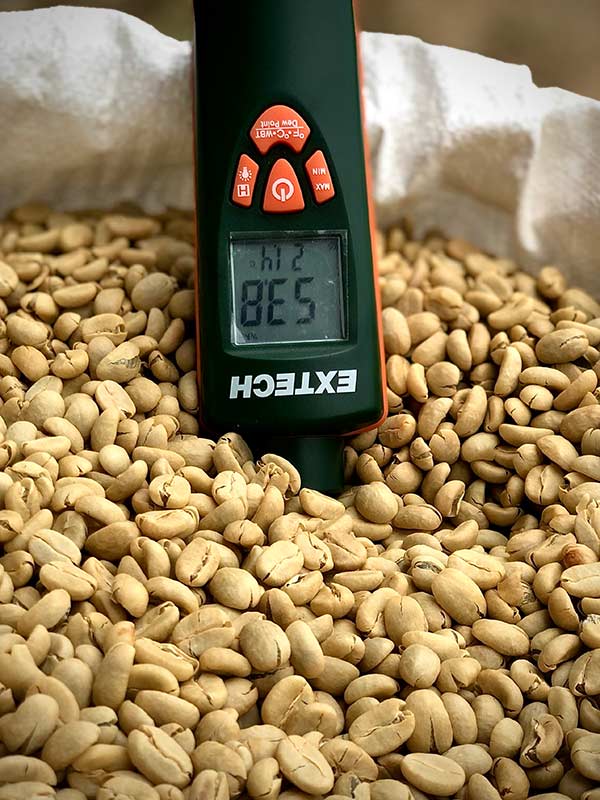

After the washing process is complete, the parchment is laid out on raised African beds to dry thoroughly under the warm Timorese sunshine. During this time, the parchment is continually turned to ensure even drying and further sorting is carried out to remove any further defects. The drying will normally take between 7-10 days and is regularly checked for moisture by our team until reaching between 10-11%. Karst will make weekly visits to each farmer in person to carry out checks to ensure consistency and continuity across all groups and every individual lot (bag) is checked to ensure that the coffee has been dried to the required level.

At this point, parchment is collected from every individual household and payment made directly at farmgate. From here, the parchment is transported to our storage facility where it is rested for a period of 4-6 weeks. QC continues with extensive cupping of all coffees and both moisture content and water activity (aW) are closely monitored with a goal to reach an equilibrium of approximately aW 0.55 to ensure the best possible longevity and freshness of the green coffee.

After the coffee has rested, the parchment is transported to our dry hulling facility in Timor-Leste’s capital city Dili. The dry hulling process essentially removes the layer of paper-like parchment to reveal the green bean. In addition to this, the dry hulling process will also remove any further defect beans and grade the coffee by screen size (15/16/17). Finally, a team of 60 staff will meticulously hand sort the beans to further remove any defects and ensure that the resulting coffee ready for export is of the highest quality (dry processing was completed at the end of September 2023 and exported at the beginning of October and landed into the UK in the middle of November).